OD Mini

Giá bán: Vui lòng liên hệ

(Gọi điện, chat Zalo nhận báo giá rẻ hơn)Compact, lightweight sensor for precise measurement

Simple, precise, and economic solutions for measuring tasks; the OD Mini displacement measurement sensors are impressive with their compact and rugged housing, which is available in a lightweight aluminum or a rugged stainless steel. These sensors are equipped with the latest CMOS receiver technology for precise measurement, regardless of the brightness and color of the surface material. The integrated amplifier unit enables the OD Mini to work on a stand-alone basis. For complex measurement tasks up to two OD Mini Pro sensor heads can be connected to one OD Mini evaluation unit and calculate together. The OD Mini is simple to configure due to its intuitive design and display with four status LEDs. The OD Mini can also be remotely programmed via the external teaching input. The large number of available interfaces also simplifies integration into industrial networks. This ensures the highest possible reliability and precision when solving a wide range of measurement tasks.

OD Mini AT A GLANCE

Cost-saving commissioning through simple operating concept and display

Small installation size and low weight also allow use in highly dynamic applications

Calculation of two sensorheads - easy possible over the external evaluation unit

High machine throughput thanks to reliable measurement, regardless of brightness and color of surface

The wide range of available interfaces enables simple integration into industrial networks

Optimum performance even at high production speeds

Compact, rugged housing

Stand-alone use or in combination with the OD Mini evaluation unit

Display and LEDs on device for visualization of current status

Different interfaces available

Simple teach-in using display or external teaching input

CMOS receiver unit for precise, fast measurement in the µm range

Various measuring ranges: Measuring from 10 mm to 250 mm possible

Advantages

Precision meets quality

With expert-developed intelligent measurement technology which proves its worth in industrial applications time and time again, SICK offers the solution to any challenge which demands maximum measurement accuracy and quality. A pioneering spirit founded on our years of experience and our own innovations in optical sensor technology. We ensure efficient processes while fulfilling the demands of even complex measuring tasks – regardless of surface, diameter, thickness, or width, and regardless of whether an object is to be positioned or measured. This is how we ensure that your products are every bit as perfect as you want them to be. Moreover, SICK’s measurement technology supports quality assurance processes and delivers cost-saving benefits

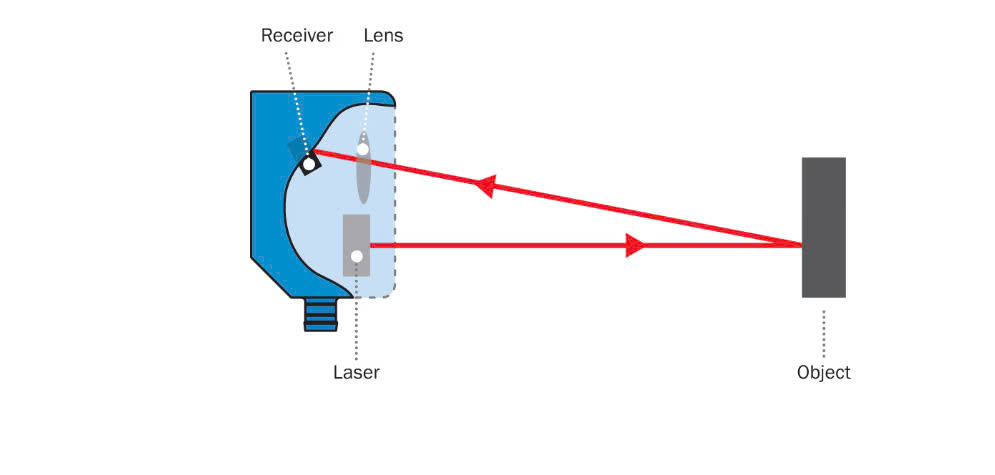

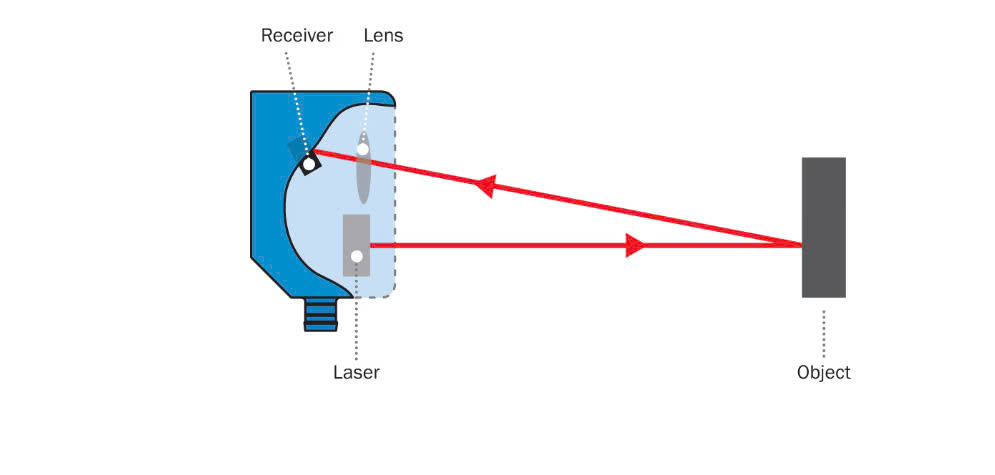

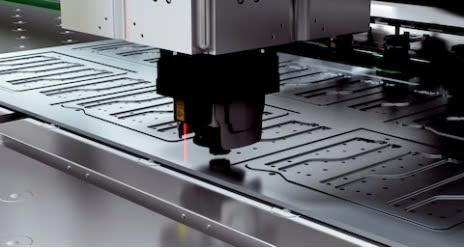

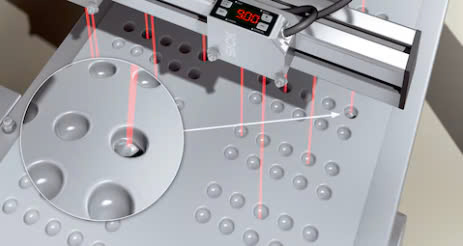

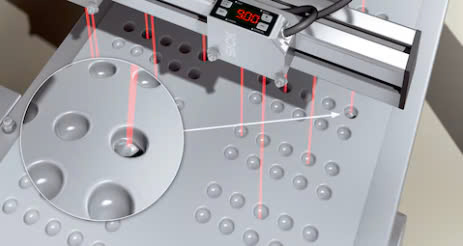

A point of light is projected onto the measuring object. The light reflected is captured by a light-sensitive receiver at a specific angle. Based on the angle between the send and receive direction, the position of the object is then triangulated (from the Latin “triangulum” = triangle).

OD Mini – The lightweight sensor in a compact housing

The OD Mini displacement measurement sensors from SICK use the triangulation principle to very precisely monitor series production in assembly processes. Due to their small design, the sensors are extremely flexible and can be used in many applications, for example when measuring components, for precise positioning, in the inspection of manufacturing tolerances in quality control, for process controls by robot positioning and for classification and sorting (e.g. by length). Since manufacturing quality plays an important role in such applications, the OD Mini is perfect here due to its high measurement precision.

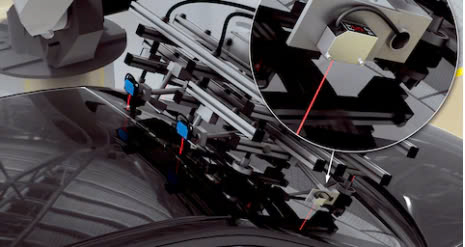

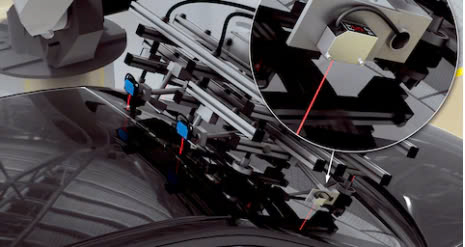

Precise positioning

- Typical applications are robot guidance for the installation of front screens and high-precision positioning of carriages

- Typical industries are robotics, handling and assembly, automotive and parts suppliers

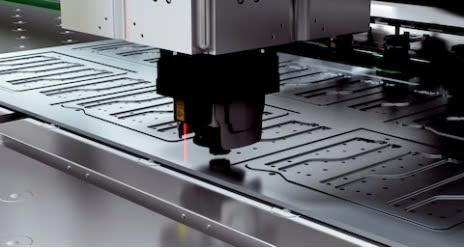

Collision avoidance

- Typical applications are height positioning and collision avoidance at the cutting head and positioning of grippers

- Typical industries are handling and assembly, machine tools

Ensuring quality

- Typical applications are quality control of components and checking the shape of blister packs

- Typical industries are consumer goods, handling and assembly, pharmaceutical and cosmetics manufacturers

SICK LifeTime Services

SICK’s services increase machine and plant productivity, enhance the safety of people all over the world, provide a solid foundation for a sustainable business operation, and protect investment goods. In addition to its usual consulting services, SICK provides direct on-site support during the conceptual design and commissioning phases as well as during operation.

The range of services not only covers aspects like maintenance and inspection, but also includes performance checks as well as upgrades and retrofits. Modular or customized service contracts extend the service life of plants and therefore increase their availability. If faults occur or limit values are exceeded, these are detected at all times by the corresponding sensors and systems.

Consulting and design

Application-specific advice on the product, its integration and the application itself.

Commissioning and maintenance

Application-optimized and sustainable ─ thanks to professional commissioning and maintenance by a trained SICK service technician.

Service contracts

Extended warranty, SICK Remote Service, 24-hour helpdesk, maintenance, availability guarantees and other modular components can be individually combined on request.

Để lại đánh giá và bình luận

Khách hàng đánh giá

0 / 5 sao

Để lại Email của bạn để nhận nhiều ưu đãi lớn.