MLG-2

Giá bán: Vui lòng liên hệ

(Gọi điện, chat Zalo nhận báo giá rẻ hơn)Flexible in use for length, width and height measurements

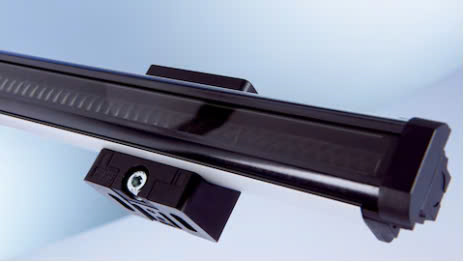

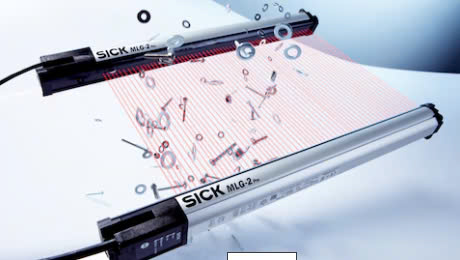

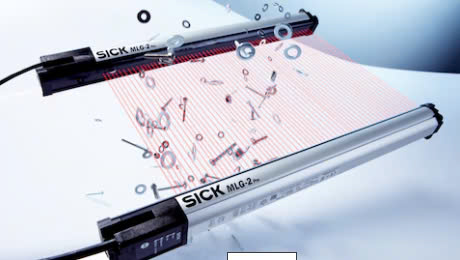

With the MLG-2 measuring automation light grid, SICK is offering the right solution for a wide range of applications in logistics and factory automation. The MLG-2 Prime, MLG-2 Pro and MLG-2 ProNet device variants are used in challenging applications with transparent objects and high object speeds, to name a couple of examples. With a resolution of up to 1.25 mm, the new “cross beam measurement” function and the “transparent” mode, the MLG-2 masters measuring task with high precision. The pre-installed solutions in the SOPAS ET configuration software allow even complex applications, such as object width measurement, to be parameterized with ease. The MLG-2 Pro and MLG-2 ProNet feature common industrial interfaces such as the RS845 or Ethernet interfaces.

MLG-2 AT A GLANCE

High measurement accuracy for detecting even very small objects reliably

Transparent mode function for reliably detecting and measuring transparent objects

The high-speed scan offers short response times for safely detecting objects traveling at high speeds

The SOPAS ET configuration software with menu-driven wizard for quick configuration

Ambient light immunity enables greater reliability

Integrated interfaces and matching function blocks reduce the time and effort involved in the commissioning process

Simple maintenance without the need for specialist staff thanks to the cloning function with IO-Link

Beam separation: 2.5 mm, 5 mm, 10 mm, 20 mm, 25 mm, 30 mm, 50 mm

Maximum range: 12 m

Functions: Cross beam measurement, 4 x zone measurement, high-speed scan, transparent mode

Interfaces: PNP, analog, RS485, IO-Link, PROFINET, PROFIBUS, EtherCAT®, EtherNet/IPTM, CANopen

Sun resistance mode with reliable switching threshold

MLG-2

Flexible in use for length, width and height measurements

MLG-2 measuring automation light grids from SICK offer the right solution for a wide variety of applications in logistics and factory automation. The MLG-2 units are used to monitor the material flow in conveyor belts, in automated storage and retrieval systems, in order processing and many other areas. For example, the light grid simultaneously determines the maximum height and overhang when measuring pallets. The sensors are modular and enable customers to select between different detection heights and beam separations. A clear display ensures easy configuration and diagnostics. Optical synchronization eliminates the need for wiring between the sender and receiver. SICK also offers a wide range of different types and interfaces.

Display

FlexFix bracket

Less installation space required: To achieve comparable sensing ranges, IMX sensors can be selected one size smaller than standard sensors.

MLG-2 Pro for demanding applications

The light grids of the MLG-2 Pro variant are used in demanding applications to detect transparent objects and at high object speeds. With functions such as “Transparent mode,” “High-speed scan,” or “High measurement accuracy,” the MLG-2 Pro performs challenging measuring tasks with the utmost precision. The pre-installed solutions in the SOPAS configuration software allow even complex applications to be configured with ease. The MLG-2 Pro uses conventional industrial interfaces so that even individualized solutions can be programmed via the control.

“High-speed scan” function offers short response times for safe detection at high object speeds.

The “Sun and dust” mode allows the MLG-2 to operate trouble-free, even in harsh environments.

“Transparent mode” function for reliably detecting and measuring transparent materials.

MLG-2 ProNet: Easy integration

As the degree of automation of a plant or machine grows, so too does the amount of cabling required – and therefore also the work involved in planning, installation, commissioning, and maintenance. But not with the MLG-2 ProNet from SICK. It offers all the advantages of a measuring automation light grid and now features integrated interfaces such as PROFINET, EtherCAT®, EtherNet/IPTM, CANopen and PROFIBUS. Thanks to corresponding function blocks, commissioning is quick and simple. Solutions are preinstalled in the SOPAS configuration software. This allows for even complex applications, such as object width measurement, to be configured with ease. It is also possible to change the format automatically via fieldbus.Thanks to its rugged design, the IMX works reliably even under harsh conditions. The sensor is resistant to oils, coolants and other contamination that can arise in production facilities and machines. Thanks to its high leak tightness, shock resistance, and good EMC properties, the IMX is suitable for numerous applications and environments. These properties increase the service life of the sensor and ensure stable processes. This reduces downtimes due to maintenance work, thereby resulting in higher plant productivity.

Rugged, durable design.

Để lại đánh giá và bình luận

Khách hàng đánh giá

0 / 5 sao

Để lại Email của bạn để nhận nhiều ưu đãi lớn.